US publishes a Notice of Petitions for test procedures

In the United States, the Department of Energy (DoE) publishes a Notice of Petitions for waiver to certain provisions in the External Power Supply (EPS) test procedure.

The DoE efficiency requirements originated from earlier work of the US Environmental Protection Agency and subsequent Energy Star program .

A calculation in 1998 from the Lawrence Berkeley National Laboratory (LBNL) showed that in the United States alone, a year of standby power consumption accounted for 5% of all residential electricity, which was equivalent to a year’s energy costs of $3 billion. The DoE predicted that the total electricity consumption in the United States by 2014 would be 1.29 billion megawatts, so a potential waste of 64 million MWh – equivalent to the capacity of 18 typical power stations – should the wastage trend continue. It was clear that something had to be done, so the DoE consequently introduced an efficiency requirement for External Power Supplies (EPS) that has since evolved over the years. The latest DoE Level VI specification introduced in 2014 became mandatory on 10/02/2016. This included more stringent energy efficiency levels for a greater number of external power supply types measured over various points of the load curve. All external power supplies sold in the US must now meet the updated and expanded DoE Level VI energy efficiency requirements and many countries are aligned to this with similar specifications.

For instance, the European Union (EU) has a voluntary Code of Conduct (CoC) v5 standard that was also introduced in 2014 and is formed of two tiers. The Tier 1 standard roughly equates to DoE Level VI and is expected to be made mandatory in the near future, followed by the tighter Tier 2 standard shortly thereafter.

The internationally approved test method for determining DoE efficiency level has been published by the IEC and the approach taken is to measure the input and output power at 4 defined points: 25%, 50%, 75% and 100% of rated power output. Data for all 4 points are separately reported as well as an arithmetic average active efficiency across all 4 points. This has always been the standard test procedure in the past. However due to the evolution of adaptable output voltage External Power Supply (EPS) technologies such as USB PD, PPS and different kinds of quick charge protocols, there are cases where the standard test procedures do not represent the active mode efficiency of those products. Under the existing test procedure the average active mode efficiency of an adaptive EPS must be tested at both its lowest and highest achievable output voltages.

If the product is designed as a low voltage-high current adaptive EPS for quick charge (such as an OPPO VOOC 5V/4A ‘flash charging’ system), then the 100% load test point is a real use case since the current at an empty battery condition could be the max current which is then reduced as the battery charges whilst the output voltage is kept low (5V in the OPPO VOOC example) throughout the process.

However, if the product is designed as a high voltage-low current adaptive EPS for quick charge (such as Qualcomm QC), then a 100% load test point at low output voltage may not represent the real use case because instead of raising the current, such an EPS would raise the voltage to realise the quick charge (for example, raise the 5V output to 9V, 12V etc with a lower output current at higher output voltage). Therefore testing such an EPS using the standard test procedure may only represent a rare condition for such products.

This is illustrated in the Power Integrations DER-494 Design Report on a 19.5 W QC™2.0 / QC™3.0 Compliant Charger using their INN2215K InnoSwitch.

As can be seen, such a design operates at low output voltage-high current (such as 6.5V/3.2A in the example) only for a brief period of time. At no point do the highest charge voltage (12V) and highest charge current (3.2A) coincide.

As high voltage-low current is the most commonly used quick charge scheme implemented in consumer electronics today, there has recently been news regarding the exact issue mentioned above. The DoE has been petitioned by a number of manufacturers for an exemption from specific portions of the IEC standard test procedure used by the DOE for determining EPS energy efficiency. The petitioners have suggested an alternative testing approach (detailed in the waiver petition) to measure the active mode efficiency of the specific products in a more representative manner. The DoE has given an interim waiver and a notice has been published in the Federal Register on July 24, 2017 soliciting comments, data, and information concerning the petitions and the suggested alternate test procedure. A waiver granted by DOE remains in effect until DOE amends the regulations so as to eliminate any need for it, pursuant to 10 CFR 430.27(m) (consumer products) and 10 CFR 431.401(g) (commercial and industrial equipment). However, with the new USB-PD 3.0 v1.1 Programmable Power Supply (PPS) specification, a maximum 20V output voltage can simultaneously be requested with the maximum 5A output current to deliver up to 100W, so the 100% load test point will become increasingly relevant as more customers migrate to this more adaptable standard

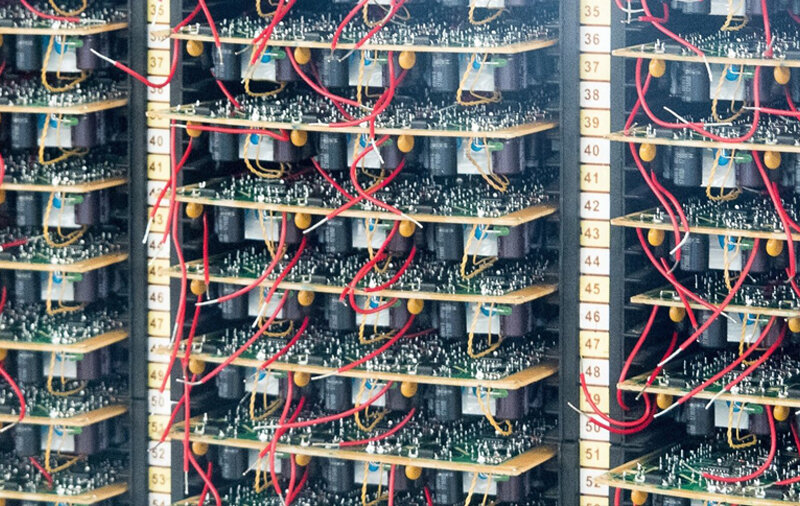

Salom has a 40+ year history in the design and manufacture of external power supply products that meet the most stringent DoE energy efficient requirement using all elements of the standard IEC test procedure. We have been supplying DoE Level VI compliant PSUs ranging from 5W to 100W following the introduction in 2014 and continue to monitor the latest regulations to ensure full compliance in each regions where our products are designed to be sold. We also have a significant Research investment including our own internal EMC pre-compliance labs enabling us to explore the limits of all architectures, so are well positioned to meet future enhanced efficiency requirements for the CoC or subsequent DoE Levels that may follow. We are a power partner of choice for many global brands, please don’t hesitate to call regarding your specific power requirements.